Good news! On the morning of January 8, at the National Science and Technology Award Ceremony held in the Great Hall of the People, Dafa Chemical Fiber, an enterprise in Ningbo Hangzhou Bay New Zone, took a second prize in the National Awards for Progress in Science and Technology as the first unit in an innovation project! It put an end to the absence of a first unit in Ningbo in the National Awards for Progress in Science and Technology over the past 7 years.

“Every ton of regenerated polyester textiles we produce can save 6 tons of crude oil and reduce 3.2 tons of carbon dioxide emissions.” said Qian Jun, Deputy General Manager of Ningbo Dafa Chemical Fiber Co., Ltd. located in Ningbo Hangzhou Bay New Zone. Depending on the innovation project “Integrated Technology for Efficient Waste Polyester Recycling and Fiber Preparation Industrialization”, Dafa Chemical Fiber created a “perfect loop” in China’s polyester textile industry.

Aim at Regenerated Fiber Recycling

Dafa Chemical Fiber has been considering the recycling of regenerated fibers.

Founded in 1995, Dafa Chemical Fiber is a professional manufacturer of regenerated polyester staple fibers.

At the beginning, Dafa Chemical Fiber used waste plastic bottles as the raw material to produce recyclable hollow polyester fibers. In the 21st century, the profit margins in the regenerated chemical fiber industry have been further squeezed. Dafa Chemical Fiber has to enhance its technology innovation capability constantly.

In 2002, the company successfully made a breakthrough in the large spinneret and double-stage filtration technology. It designed and made a production line which can produce 30,000 tons of regenerated staple fibers a year. 4 years later, Dafa Chemical Fiber proposed the application of liquid phase viscosity enhancing technology in regenerated spinning.

Facing the huge gap between supply and demand for waste plastic bottles, Dafa Chemical Fiber set its eyes on the large stock of waste polyester textiles.

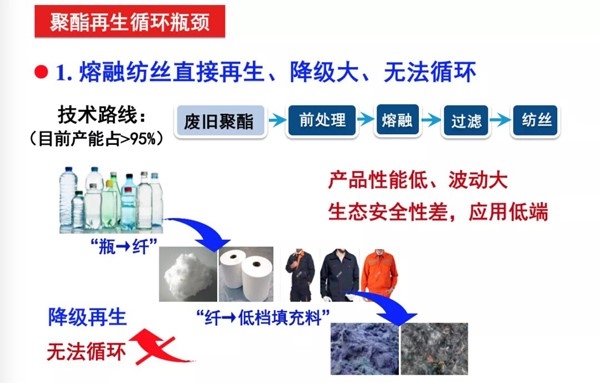

Though manufacturers all over the world were trying to recycle waste textile fibers, the effect of industrialization was not very ideal.

The costs of European, American, Japanese and Korean preparation technologies were too high, so it was hard to popularize them in China in a large scale. In China, most manufacturers adopted simple open spinning or melt spinning. The prodcut quality was low and the application was limited.

How to realize efficient recycling and high-value utilization of waste polyester textiles? This question was put before the eyes of Dafa Chemical Fiber.

From ideas to experiments, to large scale production, it took Dafa Chemcial Fiber seven years to finish the process.

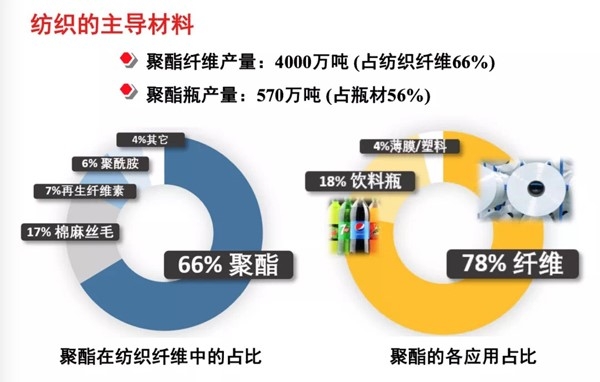

Different from waste plastic bottles, which have simple chemical components, waste polyester textiles have a diverse variety of colors and chemical components. It’s not an easy thing to mix and spin all kinds of polyester textiles with different qualities together.

In the early stage of R&D, the chemical fiber giant Teijin from Japan noticed Dafa Chemical Fiber and expressed its willingness to establish cooperation, but Dafa Chemical Fiber did not accept the “olive branch”.

“The quality of fibers produced using Japanese technology was good, but the cost was as high as ¥12,000 /ton, while finished regenerated polyester fibers in the domestic market were only ¥10,000/ton.” said Qian Jun. No matter how good a technology is, if it doesn’t fit the domestic market, it cannot realize a circular economy.

Create a Chinese Way of Recycling Waste Textiles

Dafa Chemical Fiber decided to take the road of self-dependent innovation.

In 2011, Dafa Chemical Fiber used a combination of physical and chemical techniques to produce regenerated polyester staple fibers. It got good products and was recognized by downstream customers. In 2014, Dafa Chemical Fiber successfully developed sheath-core composite low melting point regenerated polyester staple fibers.

After that, the company's technical team took the initiative to recruit talents in Shanghai and reached cooperation with Donghua Research Institute’s president and academician Yu Jianyong, a native of Ningbo.

In 2015, the Academician Workstation was formally established. This expert team, consisting of 8 academicians and 14 supporting researchers from the company, became an important engine for Dafa Chemical Fiber.

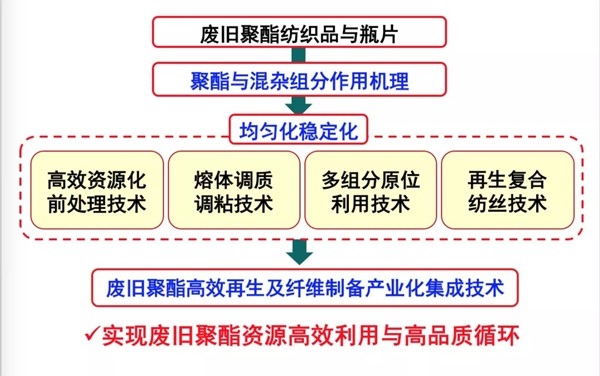

Color fastness, economy, stability, environmental protection, technical problems were overcome one after another. Dafa Chemical Fiber seized over 80% of the key technologies such as melt quality and viscosity control and regenerated composite spinning, and began to produce fibers comparable to primary polyester.

At present, a proprietary intellectual property system for efficient polyester regeneration and high-quality fiber preparation industrialization has been formed. The effects of technology application, resource utilization and environmental protection are remarkable

It is reported that using this technology, Dafa Chemical Fiber produced 550,000 tons of regenerated polyester fibers and reduced 1,765,800 tons of carbon dioxide emissions in three years.

Double the Sales and Become a Supplier for the World’s Largest Sofa Manufacturer

The project undertaken by Dafa Chemical Fiber was applauded by China National Textile and Apparel Council.

China National Textile and Apparel Council’s Technology Development Center’s person in charge said this project greatly enhanced the level of regenerated polyester fiber technology, changed the traditional idea and existing situation that recycled raw materials can only produce low-grade products, and provided a new idea for the development of China’s fiber resource recycling industry after the total ban on solid waste imports.

“This project’s implementation has promoted the recycling of waste polyester fabrics, the processing of regenerated fibers, and the development of clothing and home textile production. It plays a leading role in the comprehensive utilization of resources and improves the image of China as a major textile maker.”

The quality is comparable to primary polyester fibers, but the price is much lower than that of primary polyester fibers and regenerated fibers produced by Japan’s most advanced technology. This makes Dafa’s regenerated polyester fibers extremely competitive.

In May 2018, the world's largest sofa manufacturer, American-based Ashley, partnered with Dafa Chemical Fiber. The latter became the former's largest supplier of regenerated fibers.

It is reported that in the past month, Dafa Chemical Fiber exported 14,800 tons of regenerated fibers. In 2018, its annual sales reached ¥2.3 billion, which almost doubled the number in the same period of the previous year.

It’s understood that at present Dafa Chemical Fiber’s capacity of regenerated filling staple fibers has reached 400,000 tons. Sales are expected to reach ¥3 billion in 2019.

“We will fix our eyes on the forefront of the world's regenerated fiber technology and keep developing proprietary innovative products with better performance.” said Qian Jun.